Compliance Initiative of SAPL Off-Dock Facility

Overall Security System

The security system of Summit Alliance Port Limited (SAPL) depends on manual and technological intervention. In most areas both systems are combined to provide the security we maintain for our personnel, cargo and assets. Following is a brief of our security procedures:

Gate control is maintained by security personnel, who checks and verifies every person entering the CFS. Visitor’s details are recorded in the registers maintained at the gates. Trucks/vans arriving with export cargo are checked at the gate ensuring delivery notice, timings of entry, shipper's name and type/quantity of cargoes are recorded in the registers. If truck/van number, driver's name, driving license match the cargo description then security personnel issue a token to enter the CFS from the parking lot. Every car entering the gate is checked for details of passengers, drivers and any commodity carried in the car. These details are recorded. Cars are checked for any unwanted substances.

Warehouses where export cargo are received and stacked are fully covered by CCTV cameras. These are monitored live 24/7 by a dedicated team of staff on 8 hourly shifts. Additionally, security guards are stationed on stages constructed above the ground level to have a bird’s eye view of the cargo area. During cargo receiving, cartons are counted to match the packing list. Any damages to tapes and/or to cartons is further investigated for any tampering and pilfering of contents.

Containers are stuffed as per Load Plans received from our customers. Containers are inspected prior to stuffing for damages, agricultural pest/waste and hidden compartments including 7 points. Tally is maintained at the container door to ensure correct cartons are being stuffed. Sealing of containers with security seals is recorded. Prior to and during the stuffing process minimum 5 images are taken of the container, including images showing doors closed and with seals affixed.

Container transportation to the port is done by prime movers which are dedicated only for our use. These prime movers are fitted with GPS based tracking devices. Progress of the prime movers on the road and into the port gate are monitored live by a team of dedicated staff. Gate-out time of containers along with seal number and details of driver are recorded at the gate. Similarly during gate-in at port, details of the container and seal are recorded along with the time of entry. Night time patrols on the road from CFS to port are maintained by staff who continuously travel back and forth on motor bike to ensure no prime mover stops on the way.

Supply Chain Security (SCS)

In our pursuit to have the highest possible security standards and to be compliant with ISPS Code and US CBP security requirements, we have taken steps to enhance our security measures.

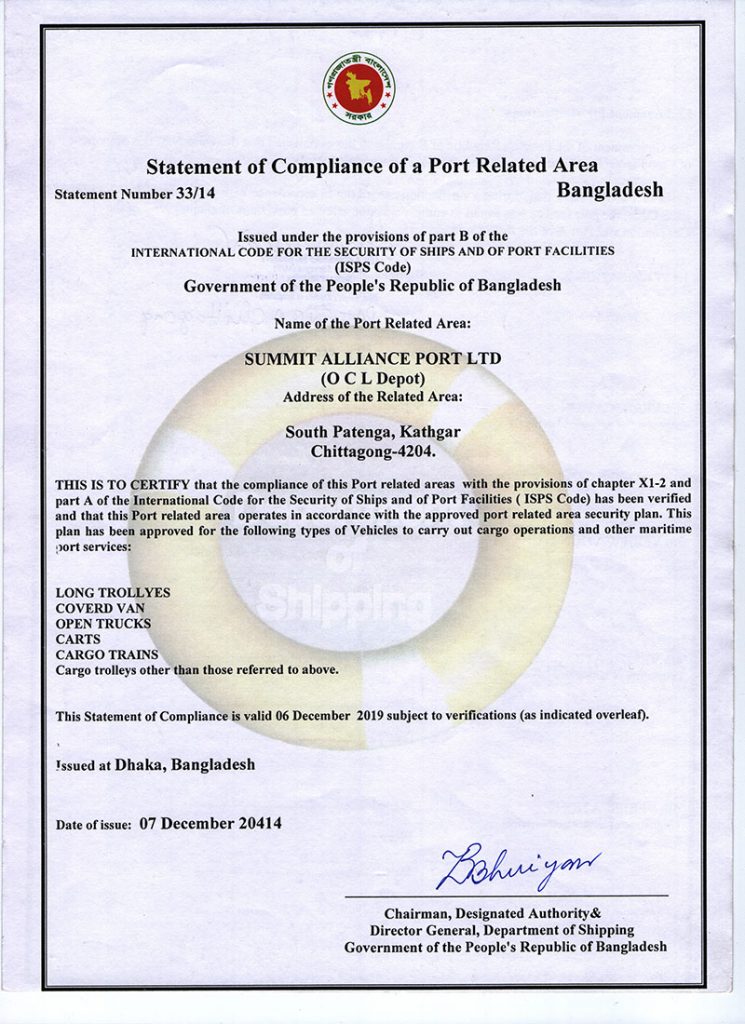

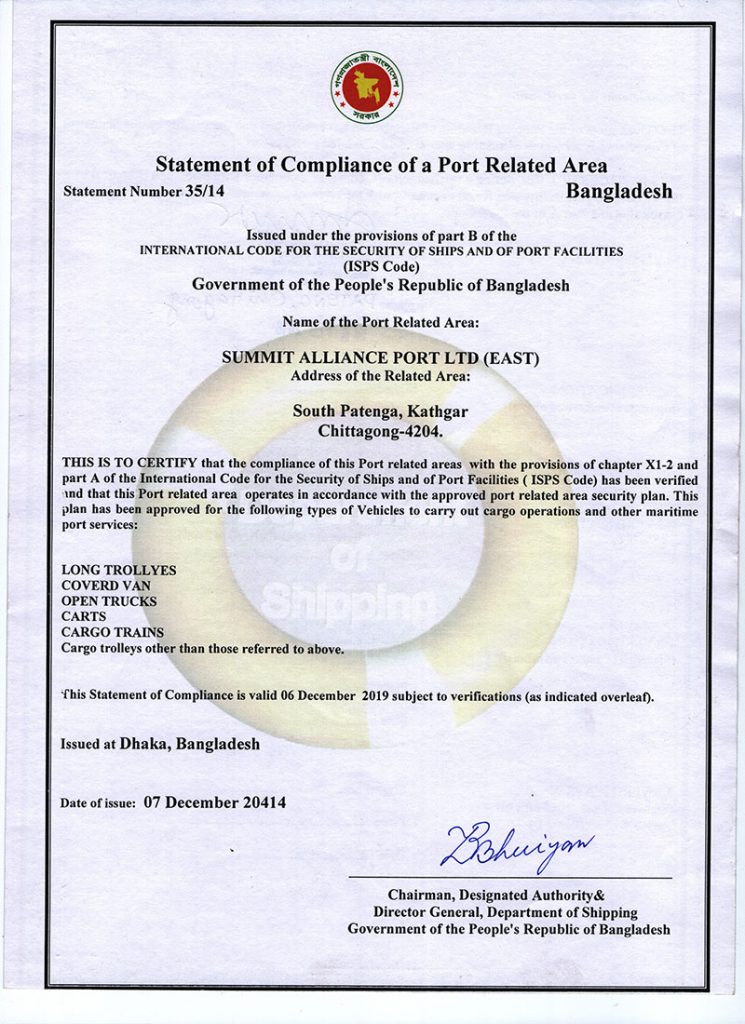

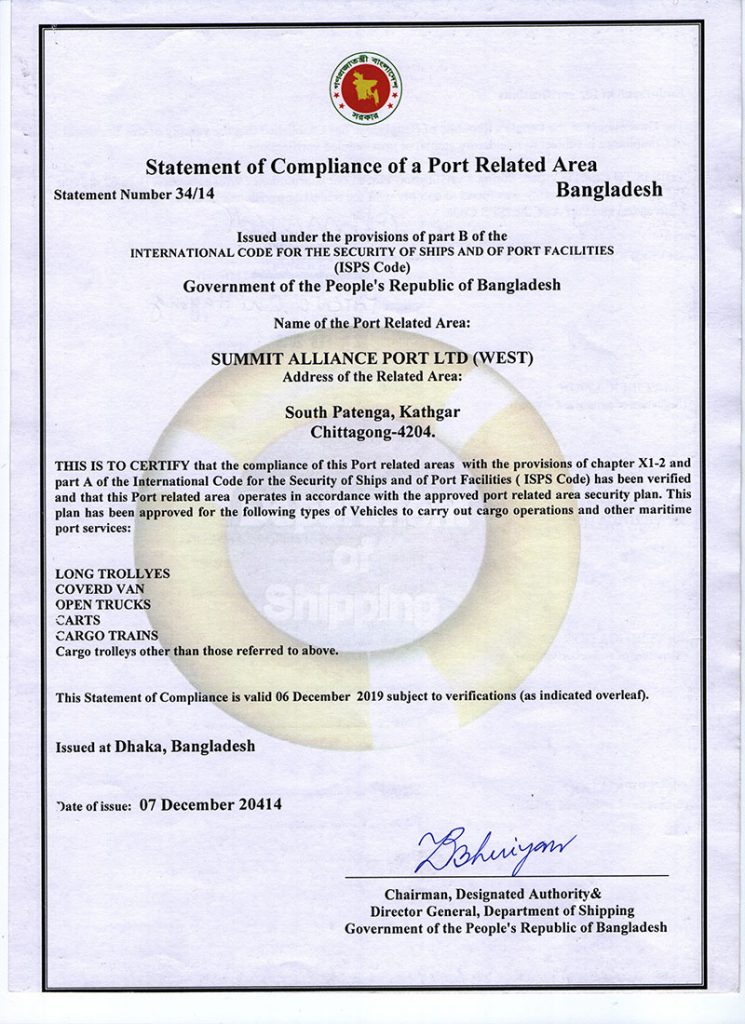

International Ship and Port Facility Security Code (ISPS)

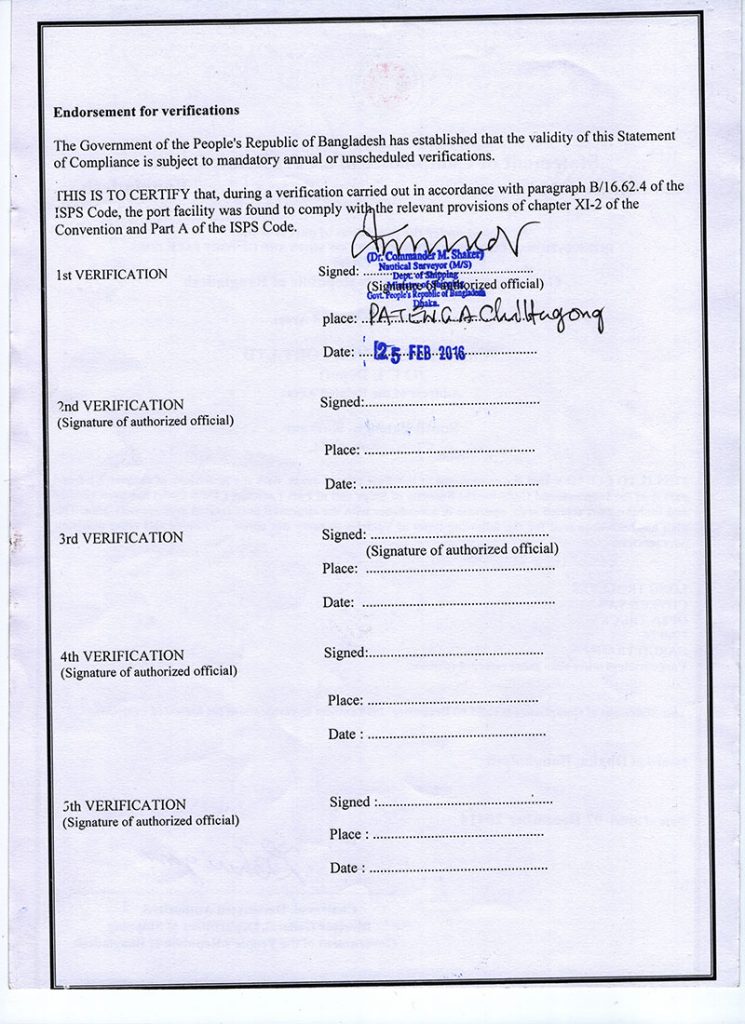

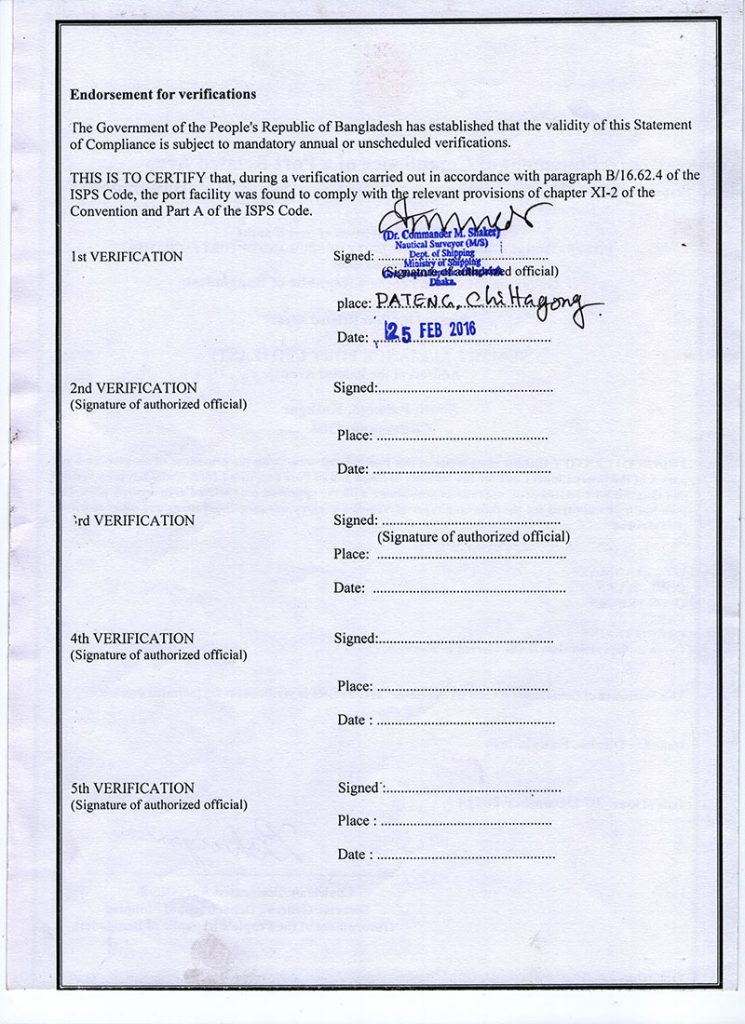

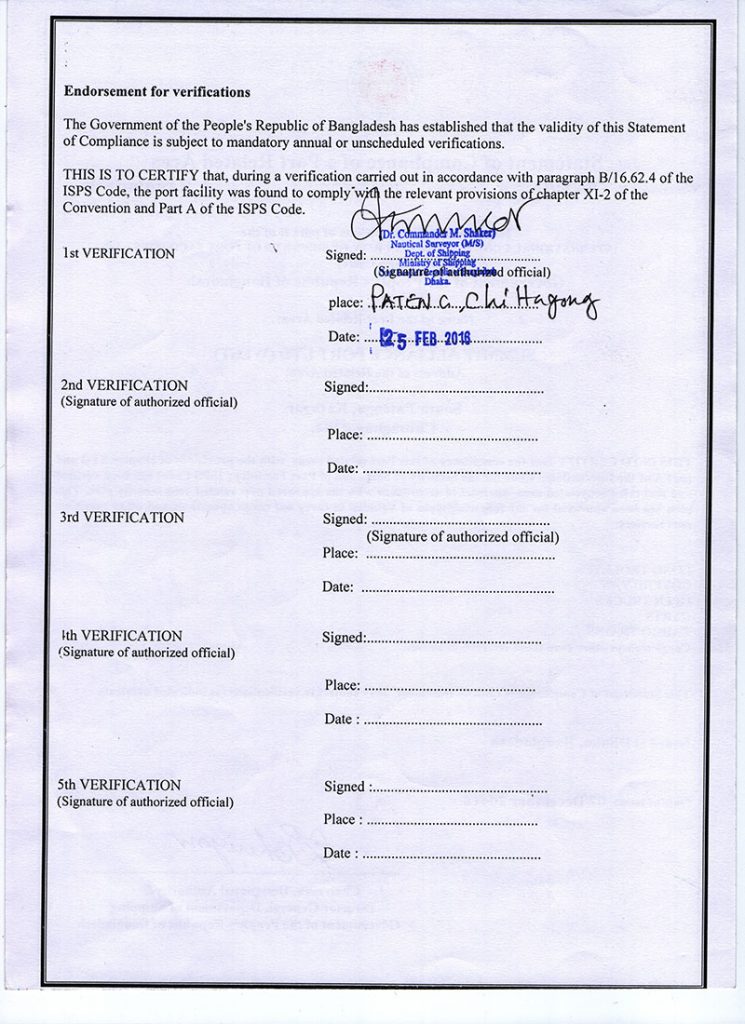

SAPL is ISPS certified since 2013 and review on SoC (Statement of Compliance) is done in regular intervals. Therefore, the last review on SoC (Statement of Compliance) under ISPS Code was done on March 10, 2020 headed by the DG (Director General) Shipping representative and Nautical Surveyor of the Department Dr Commander M. Shaker (retd) BN, from Department of Shipping, Ministry of Shipping Government of the People’s Republic of Bangladesh.

In connection to Supply Chain Security under ISPS Code, United States Coast Guard representatives from the US Department of Homeland Security visited our facility on 2nd September’ 2014 headed by Commander Karen Jones, International Port Security, United States Coast Guard to review our SoC (Statement of Compliance) under ISPS Code and the other member of the team were:

Lieutenant Commander Bryson T. Spangler, United States Coast Guard

Lieutenant Colonel David Lopes (psc), United States Army

Dr Commander M. Shaker (retd) BN, from Department of Shipping, Ministry of Shipping Government of the People’s Republic of Bangladesh

Lieutenant Colonel Md. Moazzem Hossain, Director (Security), Chittagong Port Authority

Lieutenant Commander Nizam Uddin, PFSO, Chittagong Port Authority

Customs-Trade Partnership Against Terrorism (C-TPAT)

SAPL voluntarily participates in a comprehensive supply chain security verification program named Global Security Verification (GSV) conducted by Intertek Services on a regular basis to ensure appropriate security measures are maintained as published by the U.S. Bureau of Customs and Border Protection Agency. U.S. Customs and Border Protection Agency had visited our facility on 4th November 2009, and the visit was headed by Mr. Clifford T. Hammond, Supply Chain Security Specialist, C-TPAT Buffalo Office.

Social Compliance

In terms of social compliance SAPL aims to create a workplace that protects workers’ health and safety with due respect for the environment and promotes an atmosphere to enhance learning and opportunity for employees in a way that is fulfilling, recognized and fairly rewarded. SAPL wants to be the preferred contractor and the favoured employer of the industry by meeting the terms of the laws, regulations and social responsibility. SAPL’s goal is to protect employees, people, property and the environment in which we work and live. SAPL is committed to continuous improvement and best practices, which will enhance its business by reducing risk and adding value to services. SAPL basically works on the following areas in terms of social compliance:

- Legal Compliance: There are routines in place to ensure the applicable laws and regulations related to compliance requirements.

- Business Ethics: Trust and transparency related to the business functions are ensured at all times. There is no case of corruption or the use of bribery related to the facility business and related official documents required by law are not manipulated.

- Prevention of Child Labour: SAPL does not allow employment of any child labour and it is applicable for all its clients and associates.

- Best Interest of Worker: Recruitment, working hours, wages and benefits are ensured as per applicable labour law. There is no forced, prison, bonded or involuntary labour. Harassment, abuse or discrimination are not allowed. SAPL encourages freedom of association and the company has grievance handling procedures in place.

- Emergencies and Fire Prevention: Emergency preparedness and response plan, business continuity plan, fire incidents and accidents handling plans are in place. SAPL focuses on competence and training, firefighting equipment, escape routes, emergency exits, evacuation alarm and drills.

- Worker Health & Safety: Workplace risk assessment, incidents and accidents, health & safety training, machinery and other equipment, safe working routine, safety information, safety hazard, personal protective equipment (PPE), first aid equipment, first aid trained person, ergonomics, drinking water, housekeeping and hygiene, break area.

- Best Interest of Environment: SAPL recognizes the importance of operating in an environmentally sustainable manner and is committed to protection of the environment by ensuring a high level of environmental performance by minimizing any adverse impact as a result of its activities. SAPL addresses the following for environmental care:

- Environmental policy.

- Environmental improvement plan (reviewed every year).

- Air quality monitoring of outdoor and internal shed for both day and night shifts twice in a year.

- Noise test for outdoor and internal shed for both day and night shifts twice in a year.

- Noise monitoring for inside and outside of the genset room while in operation.

- Stack emission test for genset twice a year.

- Surface and groundwater test

- Energy reduction plan and monitoring for electricity with a target.

- Reduction plan of other environmental impacts e.g. Paper and Fuel (Diesel) with a target.

- Chemical management procedure including Storage, Handling and Transportation.

- Labeling of chemicals and valid MSDS in local language.

- Waste management procedure including storage, handling and transportation.

- Licensed contractor for waste disposal.

- Oil water separator (OWS).

- Regular waste management and environmental awareness competence training.

Compliance Initiative of SAPL River Terminal

Compliance system in SAPL River Terminal (RT) consists of the following:

- Legal Compliance

- Supply Chain Security (SCS)

- Social Compliance

Legal Compliance

SAPL RT obtained all relevant legal licenses, clearance and certificates from regulatory bodies of the country, such as business trade license, Customs Bond License, Environmental Clearance Certificate, Fire License, Generator or CPP License, Department of Factories & Establishment (DIFE) etc. Apart from it, the RT has a group insurance for Workmen compensation for its employees and have man power agreement with 3rd parties.

Supply Chain Security (SCS)

SAPL RT is International Ship and Port Facility Security Code (ISPS) certified since 2017 and has also received Global Security Verification (GSV) certification, both of which meets client’s requirements when it comes to keeping safe and secure shipment of their valuable cargo. The RT also has permission for Verified Gross Mass (VGM) from the Department of Shipping, Government of Bangladesh, as per directives in Safety of Life at Sea or SOLAS Convention.

Social Compliance

SAPL RT focus on the following issues with regard to social compliance:

- Prevention of child labour: SAPL RT doesn’t employ any child labour. Proof of age documentation for all workers is in place.

- Forced labour: There is no forced and prison labour in the facility.

In SAPL-RT, workers:

- Have the freedom to leave the premises when their work shifts end

- Have not been charged directly or indirectly any fees or commission related to the recruitment process.

Business Ethics:

- Transparent and reliable.

- All documents and records updated: SAPL RT maintains 100% transparency in documentation of relevant records.

Best Interest of the Workers:

- SAPL RT provides on-site first aid facilities for both SAPL employees and contractors. It has agreement with nearby hospitals for the treatment of its employees and contractors in case of any fatality.

- SAPL RT ensures safe drinking water for its own employee, customer, vendor, visitor and contractor through installing a WPS (Water Purification System).

- Workplace risk assessment / HIRAC, Health Safety Training, Safe Working Zones, Personal Protective Equipment, Work Ergonomics, housekeeping are regularly conducted or provided.

- Resting area for workers / drivers inside the facility.

Best Interest of the Environment:

SAPL RT recognizes the importance of operating in an environmentally sustainable manner and is committed to protection of the environment by ensuring a high level of environmental performance by minimizing any adverse impact as a result of its activities. SAPL RT addresses the following for environmental care:

- Environment and Social Performance Policy.

- Energy monitoring for utilities.

- Chemical management procedure including storage, handling and transportation.

- Ensure valid MSDS in dual language for easy communication.

- Waste management/spill containment procedure including storage, handling and transportation.

- Regular environmental awareness and competence training.

- Operational Oil Water Separator or OWS to control/reduce river water pollution.

- Awareness and training to all staff, stakeholders and local community.

Emergencies and Fire Prevention:

- Emergency planning: Emergency preparedness planning is in place. The plan is based on possible identified risks.

- Incidents and accidents: Any incident or accident is recorded and documented in a register.

- Competence and training: Relevant trainings are conducted according to the facility's yearly training calendar.

- Firefighting equipment: Various locations of the facility are equipped with fire extinguishers. In addition buckets with sand and water drums are kept around the facility.

- Escape routes and emergency exits are in place at CFS shed and various other locations.

- Evacuation alarms: Alarms are installed around the facility.

- Evacuation drills: Drills are conducted at regular intervals at least twice a year. In addition, every 18 months interval, mock drill is conducted in collaboration with Fire Services and Civil Defence (FSCD Bangladesh).